Your vehicle’s oil pressure switch may be small, but it plays a crucial role in protecting your engine. Ignoring oil pressure issues can lead to rapid engine wear or even failure. By paying attention to this often-overlooked sensor, you can help prevent costly repairs and keep your engine in top condition. Stay alert to its warnings—your engine’s health depends on it.

In this article, we’ll go through the definition and working principle of this important small device.We’ll also explore the signs of failure, common causes, replacement steps, and maintenance tips for this crucial component.

What Is an Oil Pressure Switch?

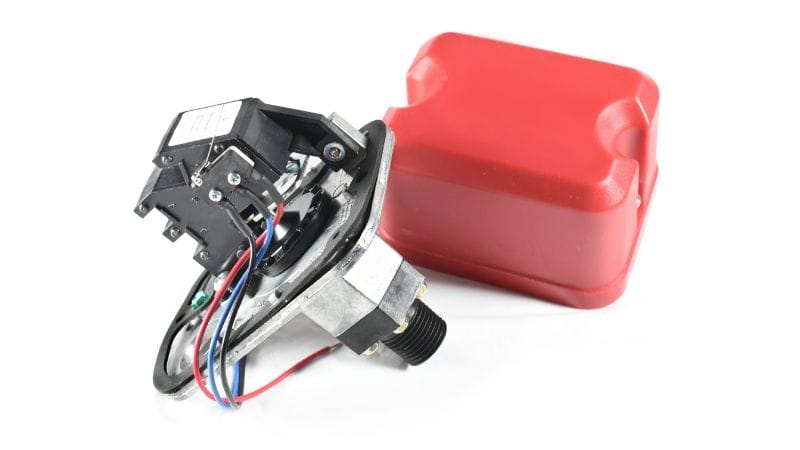

An oil pressure switch is a small but key device in your vehicle’s engine, usually located on the engine block or near the oil pump. Its job is to monitor the oil pressure inside the engine’s lubrication system.

The switch usually works as a simple on/off sensor, closing or opening an electrical circuit based on oil pressure. This makes it a reliable way to monitor your engine’s health.

How does an oil pressure switch work?

The oil pressure switch monitors if the oil pump is supplying enough pressure to move oil through the engine’s lubrication system. When your engine runs, the oil pump draws oil from the oil pan. It pushes this oil through the oil filter and into channels that reach all critical parts. The oil pressure switch senses the pressure inside these channels. When the oil pressure drops below a safe level, the switch activates and sends a signal to your car’s computer or dashboard. This often triggers a warning light, letting you know there might be a problem with your engine’s oil system.

Problems with the oil pump, clogged filters, or leaks can lower pressure and trigger the switch. By monitoring this pressure, the switch helps protect your engine and avoid costly repairs.

Oil Pressure Switch Vs. Oil Pressure Sensor

You might hear about oil pressure switches and oil pressure sensors when checking your engine. Both parts monitor the oil pressure, but they work differently.

The oil pressure switch is a simple device. It turns on or off depending on whether the oil pressure is above or below a set point. The oil pressure sensor, on the other hand, gives continuous information. It measures the exact pressure and sends a detailed signal to your vehicle’s computer system or engine control unit (ECU), which helps you manage engine health and performance by adjusting operations based on oil pressure data.

Here’s a quick comparison:

| Feature | Oil Pressure Switch | Oil Pressure Sensor |

|---|---|---|

| Function | On/off alert for low oil pressure | Continuous oil pressure reading |

| Signal type | Simple electrical switch signal | Variable electrical signal |

| Feedback type | Warning light activation | Gauge or computer display |

| Use | Alerts driver of critical issues | Provides real-time oil pressure data |

Both parts are important for your engine’s health. The switch warns you about problems. The sensor helps maintain proper oil pressure by giving exact data. Knowing the difference helps you understand your vehicle better.

How to Diagnose a Faulty Oil Pressure Switch

If your oil pressure warning light turns on, the first step is to check the engine oil level. Low oil can affect oil pressure and cause the warning light to come on. Make sure your engine oil is at the correct level before assuming the switch is faulty.

Next, pay attention to your oil pressure gauge. If it shows unusually low or fluctuating readings while your engine is running normally, this could indicate a problem with the oil pressure switch or sensor.

Use a multimeter to test the oil pressure switch electrical circuit. When the engine is off, the switch should have continuity. When the engine runs and oil pressure rises, the circuit should open. If it does not behave this way, the switch is likely faulty.

You can also look for symptoms like poor engine performance or unusual engine noises. A failing switch might give false alerts, but ignoring these signs could risk serious engine damage due to very low oil pressure.

A visual check can help too. Look for oil leaks around the switch, which can lead to incorrect readings.

Regularly checking your oil pressure switch helps you catch problems early. Maintaining proper oil pressure levels is important for the health of your engine and overall vehicle performance.

What Are Possible Causes of Faulty Oil Pressure Switches

A faulty oil pressure switch can happen for several reasons. Apart from the low oil level, one common cause is wear and tear over time. Since the switch is exposed to heat and engine oil, its internal parts can break down or corrode. Another reason is contamination from dirty or old engine oil. Sludge and dirt can clog the switch or interfere with how it senses oil pressure.

Sometimes, an electrical problem causes a faulty switch. Loose or damaged wiring may send wrong signals to your vehicle’s engine computer. This can affect engine performance and even cause the oil pressure warning light to flicker or stay on.

Damage inside the engine, like engine wear or damage, can also lead to low oil pressure. If the oil pump weakens or engine parts start to fail, the switch will detect falling oil pressure and alert you.

Checking these can help ensure your engine stays properly lubricated and protected.

How to Replace an Oil Pressure Switch

Here is a step-by-step guide:

- First, gather the basic tools you need: a wrench, a new oil pressure switch, rags, and safety gloves. Make sure your engine is cool before starting to avoid burns.

- Locate the oil pressure switch. It is often on the engine block near the oil filter. Check your vehicle’s manual if you have trouble finding it.

- Before removing the old switch, disconnect the negative battery cable. This prevents any electrical issues while you work.

- Next, carefully disconnect the wiring connector from the oil pressure switch. Avoid pulling on the wires to prevent damage.

- Use the wrench to loosen and remove the old oil pressure switch. Be ready with a rag to catch any oil that might leak out.

- Compare the old switch to the new one to ensure they match. Thread the new switch into place by hand to avoid cross-threading.

- Tighten the new oil pressure switch with the wrench. Do not overtighten, as this can damage the switch or engine block.

- Reconnect the wiring connector to the new switch. Then, reconnect the negative battery cable.

- Once everything is secure, start the engine and check for leaks around the switch. Also, watch the oil pressure light on your dashboard to confirm the switch works correctly.

Tips for Maintaining Oil Pressure Switches

You should check your oil pressure switch regularly to make sure it is working properly. Keep the area around the switch clean. Dirt and oil buildup can cause problems with the switch’s connection and lead to incorrect readings.

When changing your oil, inspect the wiring and connectors of the oil pressure switch. Look for loose wires or corrosion, and fix any issues you find to keep the electrical signal steady.

Maintenance Checklist:

| Task | How Often | Why It Matters |

|---|---|---|

| Visual Inspection | Every oil change | Detect wiring or switch damage |

| Clean Switch Area | Every 6 months | Prevent dirt from affecting function |

| Test Oil Pressure Switch | If warning light acts strangely | Confirm switch works correctly |

| Replace if Faulty | As needed | Avoid engine damage due to missed warnings |

Frequently Asked Questions

What are the common symptoms of a failing oil pressure switch?

You may see the oil pressure warning light come on even when oil levels are fine. Sometimes the warning light stays off when oil pressure is actually low. Other signs include oil leaks near the switch and engine noise caused by poor lubrication.

Where is the oil pressure switch typically located in a vehicle?

The oil pressure switch is usually screwed into the engine block or cylinder head. It is near the oil filter or oil pump where it can directly sense oil pressure in the lubrication system.

What is the difference between an oil pressure switch and an oil pressure sensor?

An oil pressure switch works like an on/off device. It triggers a warning light when pressure falls below a set point. A sensor provides continuous oil pressure readings to the car’s computer or gauge.

How does an oil pressure gauge relate to the function of an oil pressure switch?

The oil pressure gauge shows you the exact pressure level in real time. The oil pressure switch acts as a safety device by alerting you only when pressure drops dangerously low. Both work together to protect your engine.